square bales.

Shape-holding.

The 2.12-metre-long baling chamber, together with its high friction resistance and the packer ram driven by the large main gearbox, has the potential to produce super-hard bales even at high throughput rates. The baling ram is guided securely via four large guide rollers, and together with its adjustable side plates delivers a perfect bale density in all conditions. Straw, hay and silage are compressed into small slices in record time: 61 ram strokes per minute and hydraulic pressure applied from above ensure highly and uniformly compacted bales with more kilograms per cubic metre.

New chamber concept for high density.

The harvested crop is highly compacted in the bale chamber to produce solid, stable bales with hydraulic adjustment of the baling channel from the comfort of the cab. Each bale is compressed and shaped to a uniform density and length; the perfect result for a balanced and seamless truck-loading procedure.

Compact.

The baling pressure can be easily and quickly adjusted to the prevalent conditions at any time via the control panel. The well-positioned guide wheel facilitates high-accuracy monitoring of the bale-length configuration. Bale lengths are fully adjustable within a generous range of 70 to 240 cm. The clean-cut, perfectly right-angled bales leave the baling chamber as highly compact and dense blocks to be deposited onto the field via the roller chute.

Smooth drop.

An important feature for all contract balers: with the optional bale ejector, you can clear the baling chamber completely, since it also ejects the last two bales. This also means no residual material when it comes to cleaning and preparing the baler for winter. The bale ejector is operated with controls directly on the exterior of the baler.

The roller bale chute slides the bales gently onto the field.

Two bales in one go.

With the DUO PAC bale accumulator hooked up, two bales can be stacked one on top of the other and subsequently deposited onto the field as a large-size stack. This produces stacks 80 cm in width and 100 cm in height that can be loaded directly onto conveyor vehicles using suitable clamps.

Tying – perfect knots.

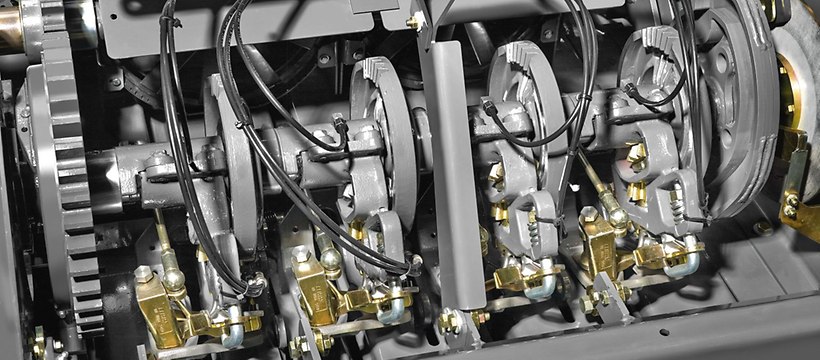

The CLAAS knotter.

CLAAS balers would be inconceivable without the legendary CLAAS knotter. The individual knotter was the first CLAAS patented product, and in 1921 was awarded a DLG medal. Today, CLAAS remains the only agricultural machinery manufacturer worldwide to develop and manufacture its own knotters.

The CLAAS knotter has, in the past, helped shape the global success of CLAAS balers immensely, and ensures super-tight knots.

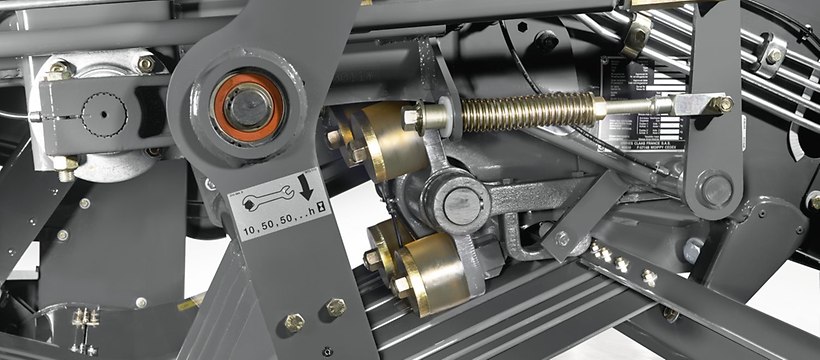

Clean and efficient.

The efficient TURBO FAN dual fan removes harmful stalked parts, short straw and dust from the knotter area to ensure perfect work results and outstanding functional reliability even in extremely dry conditions. What’s more, the system virtually eliminates the time required for cleaning.

Efficient.

CLAAS baling twine is specifically designed for CLAAS knotters. The twine is highly tear-resistant and sufficiently flexible to minimise wear to the knotter. With each new refilling, four twine spools per knotter can be tied together without having to alternate between them, which saves time. An intelligent balance of high knot tightness and efficient run length makes CLAAS baling twine a cost-effective choice. CLAAS baling twine is available for all balers, and for different operating conditions.

Bound to hold.

CLAAS high-performance knotters are renowned for their unparalleled knot tightness and quality. The four knotters are driven directly via a cardan shaft and operate extremely quickly, reliably and with razor-sharp precision. The new knotter concept with active twine pusher, aggressive clamping plate and electromechanical twine start enhances tying reliability under all conditions. The direct drive ensures permanent synchronisation between the baling ram and needles. If the needles remain motionless in the baling channel, the baling ram is blocked automatically to prevent a collision with the needles.

A further advantage: the knotters do not produce dangerous twine residues that can cause animal fatalities during feeding or leave residues when the bales are burned for power generation.

Productive.

The large twine boxes on the QUADRANT 4000 can be opened up to the side in order to feed the twine to the knotters more easily when restocking, and to make it easier to clean the machine. In total, the boxes house 16 rolls of 130 to 150 m/kg baler twine – enough for a very long day in the field.