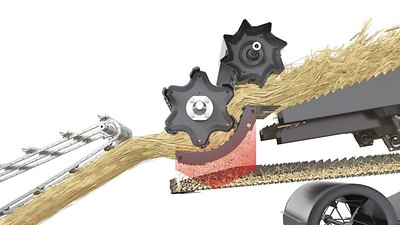

Unique APS threshing system.

The AVERO 240 is the first in its class with APS. The distinct competitive edge of this trend-setting threshing system is revealed well before the threshing drum as the dramatic acceleration of the crop flow from 3 m/s to 20 m/s triggers a chain of extremely efficient processes:

- The pre-accelerator separates the crop more thoroughly

- The crop flow is particularly even and up to 33% faster

- Higher centrifugal forces sort considerably more grains

- Up to 30% of all grains are already sorted in the pre-separation concave directly below the accelerator, significantly reducing the load on the main concave

Thus there is a net performance increase of up to 20% with no rise in fuel consumption. APS really pays.

- Versatile pre-separation concave.

The pre-separation concave is designed as a MULTICROP concave and can therefore handle any crop. The option of quickly changing two concave sieves minimises setup time and maximises efficiency.

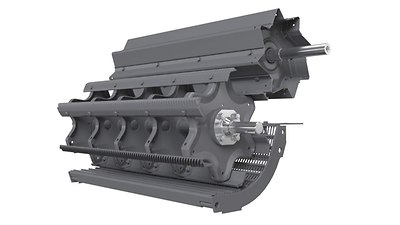

- Long threshing channel.

In the CLAAS APS threshing system, we have succeeded in wrapping the main concave much farther around the threshing drum than in conventional machines. No other threshing unit offers a contact angle of 151°. You benefit from gentle but thorough threshing with a large concave clearance and low drum speed with reduced fuel consumption.

- Improved grain quality.

For optimal deawning and decortication, the APS threshing system is equipped with multi-level adjustment options and additional components. These include, for example, the intensive threshing unit and the deawning plates. The deawning plates are activated in mere seconds with a lever above the feeder housing.

Together with the other APS benefits, the result is impressive: optimal separation efficiency combined with outstanding harvest quality.

CLAAS threshing system. Outstandingly versatile and absolutely reliable.

The champion in all fields.

The AVERO 160 uses the classic CLAAS threshing unit which consistently provides impressive proof of its ability to handle the two key threshing tasks of removing and separating grains reliably in all harvest conditions. Regardless of the harvesting challenges you face, you'll be impressed by the versatile performance it delivers across the full threshing drum width of 1.06 m.

- The threshing unit can be accessed easily from the front via the feed rake and from both sides through large openings

- The extremely robust design of all the drives, and of the threshing drum drive in particular, ensures top reliability during the harvest

Fit for any crop.

The MULTICROP concave.

The concave below the threshing drum is designed as a MULTICROP concave with individual segments that can be changed easily. You can switch the concave quickly for a wide assortment of crops – always ensuring the right combination of clean threshing, protective handling of the crop and a high separation rate.

The AVERO 160 is equipped with the classic CLAAS threshing unit.

Straw walker technology. Saving the right way.

The CLAAS compact principle.

The APS threshing system works so efficiently that the residual grain separation system in the AVERO 240 requires fewer straw walkers than you'd expect. Thanks to APS, 90% of the grain is already separated from the straw. Four straw walkers with four steps take care of the remaining 10%.

The AVERO 240 processes as much as a comparable machine with five straw walkers without APS, but has the compact dimensions of a machine with four straw walkers. This has a noticeable economic impact. The AVERO 160 also delivers above-average performance for its size: the classic CLAAS threshing unit works perfectly in combination with the four straw walkers.

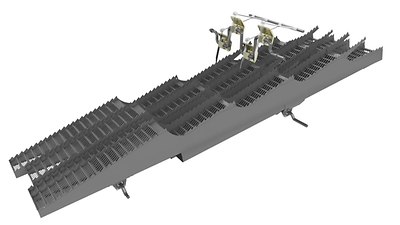

- Four straw walker steps.

The four straw walkers of the AVERO have been completely redesigned and adapted to the high-performance APS threshing system. Residual grain separation is accomplished over a total length of 3,900 mm across four straw walker steps. Centre and side extensions available. Even large volumes of straw are transported rapidly and loosely.

- Active fluffing.

In addition, the straw undergoes intensive separation with controlled agitator tines. Agitator tines located above each straw walker dig deep into the straw, loosening and fluffing it to ensure a rapid straw flow and a thin layer of straw for the last grains to escape and effectively increase separation efficiency.

- Complete control.

The AVERO provides you with numerous monitoring aids to support optimal utilisation of the installed features of the machine and to achieve the best possible threshing quality:

- Throughput monitor for the residual grain separation system and cleaning in the CIS

- Yield recording and fuel consumption measurement with CIS

- Returns fed back to threshing unit

- Illuminated inspection window for monitoring returns

- Crop monitoring in the grain tank via a large inspection window

A look into the grain tank: clean work.

Large grain tank.

Once the threshing unit, straw walker and cleaning section have done their work, the cleaned grain is collected in the grain tank. A particularly impressive feature of the AVERO is its capacity of up to 5,600 litres. However, this is but one of its many strengths.

- Easy grain sampling

- High overhead discharge height

- Ideal weight distribution

- Good view into grain tank

- Grain tank cover can be operated from operator's platform

- Fast, direct offloading

- Smooth surfaces for fast, complete emptying

Direct view.

Sometimes a glance into the grain tank can tell you more than any number of sensors. A large inspection window in the back of the AVERO cab enables visual yield monitoring, so the returns can be viewed conveniently from the operator's seat. The inspection window is illuminated for better visibility.

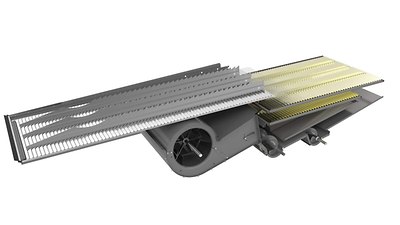

- Powerful fan.

The AVERO has a rotary fan for optimal grain cleaning. Its speed can be controlled from the cab, providing constant air pressure and even distribution of air across the sieves to handle varying crop loads. Forced air guidance prevents the formation of crop mats.

In addition, the AVERO is equipped with the impressive features of the 3D-cleaning system developed by CLAAS:

- Dynamic side slope levelling via active control of the upper sieve

- Completely consistent performance on side slopes up to 20%

- No wear - completely maintenance free

- Fast, simple retrofitting

- Removable preparation floor.

Pre-sorting of the grains (bottom) and the chaff and broken straw (top) takes place on the preparation floor. The resulting reduction of the load on the upper sieve increases cleaning capacity. The preparation floor can be removed easily for cleaning when the harvest is completed.

Straw management. From small and short to long and loose.

Short chopped material.

The AVERO distributes the uniformly short-chopped straw over the entire cutterbar width and blows it deep into the stubble. The discharge width is easily adjustable.

The CLAAS choppers are also equipped with a shear bar. Both components can be individually adjusted and thus adapted to the varying straw conditions. This ensures that no stalk is left uncut. Chopping takes place using rotating knives and a stationary cutting comb.

Top-quality straw.

The AVERO handles long straw very gently. Thanks to the protective threshing and separation process, the straw retains its full original structure, which is ideal for high-quality bedding straw. When the straw chopper is switched off, the swath is layered loosely, allowing it to dry quickly and be baled easily.

PROFI CAM – everything in view.

All AVERO models can be equipped with a PROFI CAM on the rear hood. This camera position has been chosen precisely to allow two areas to be monitored simultaneously on a colour display from the comfort of the cab:

- Distribution of chopped material / straw deposition

- Rear of machine when reversing

Up to four cameras can be connected to the system and simultaneously feed their images to the colour monitor in the cab.