ORBIS

The top-of-the-range model in the ORBIS line-up has been renewed. is able to follow the ground contours optimally. The flat mounting angle with two different positions and the very flat design make it possible to attain stubble heights as low as 80 mm.

These characteristics and the use of both small and large three-stage transport discs mean that the ORBIS 900 can be used to harvest not only maize, but whole crop silage too.

Automatic transport protection

As with the ORBIS 750, the frame of the ORBIS 900 consists of 5 parts. This makes it unrivalled for fast folding – an operation which takes just 25 seconds in the case of the ORBIS 900.

In view of the transport width of only 3 m, it is possible to drive on the road with the ORBIS 900 without special authorisation. The compact design of this maize front attachment allows good visibility to the front and to the sides.

During folding/unfolding, the fully integrated transport protection with warning stickers and lighting automatically pivots into the appropriate position for road travel or field work. The folding process takes a maximum of 30 seconds. It is not necessary for the operator to get down from the cab.

ORBIS 900 / 750 / 600 SD / 600 / 450.

Row-independent harvesting.

Up to 9 m working width.

The ORBIS row-independent maize front attachment from CLAAS with working widths from 4.5 m to 9.0 m combines completely new design and drive ideas with the experience we have gained around the globe. Its outstanding features and excellent reliability ensure success during the maize harvest.

A central locking system ensures that the ORBIS is securely connected to the JAGUAR. Power is transmitted smoothly via a quick coupler.

The ORBIS 600 SD is offered parallel to the ORBIS 600.

The SD is particularly suited to normal and low-growing crops. The outer sections with the small discs and the additional vertical feed drums enable an extremely free-flowing crop flow. The ORBIS 600 with the large discs comes into its own in normal and very high yield maize stands.

Outstanding reliability.

Front attachments from CLAAS are used to harvest an extremely diverse array of crops around the world. The CLAAS name stands for performance, wear-resistance, reliability and work quality. Drawing on our worldwide practical experience, we have completely revised the new generation of our proven ORBIS maize front attachments with improvements ranging from the optimised crop flow to the innovative folding mechanism.

Outstanding reliability in all harvesting conditions.

- Efficient drive concept with 11% lower starting torque than comparable models

- Unique crop flow for optimal chopping quality

- Optimal ground-contour tracking with AUTO CONTOUR

- Very low stubble height across the entire working width

- Engage and reverse under full load

- Straight-line crop transfer from ORBIS to JAGUAR for top chop quality

- Uniform crop flow across the entire width of the feed roller housing

- Extremely flat design for even stubble and very low stubble heights down to 80 mm

- ORBIS 600 SD with small discs for short to medium crop heights

- ORBIS 600 with large discs for medium to extremely tall maize

- Folds out symmetrically within just 25 s (ORBIS 900) or 15 s (ORBIS 750)

- Integrated transport system available with ORBIS 600 and higher

- PREMIUM LINE ex factory

Energy-saving drive.

The efficient drive concept offers you a huge amount of power for remarkably little fuel. The JAGUAR transmits its power to the maize front attachment mechanically, the energy requirement of the latter being extremely low. This is because the ORBIS requires only a few gearbox elements and impressively low starting torque. Thanks to these characteristics, the front attachment can also be switched on and reversed at full load. The gearbox and drive components are designed for high throughput. Perfect matching of the drive speed to the set length of cut ensures an optimal crop feed into the JAGUAR.

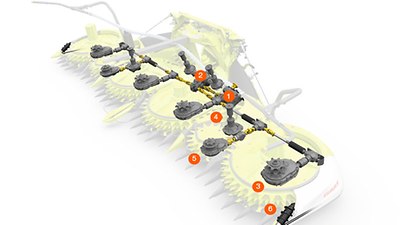

Efficient drive concept.

- Input gearbox with two speed settings and quick coupling connection to forage harvester

- Main gearbox with three speed ranges for the feed drums

- Drive, large transport discs with knives

- Drive, feed cones

- Drive, small transport discs with knives

- Optional hydraulically driven laid maize augers

Unique crop flow.

The combination of small and large intake discs makes for high versatility with outstanding throughput. The ORBIS transports all the plants gently and reliably for optimal delivery to the JAGUAR intake. If the machine is reversed, the plants which have already been cut remain on the large discs and are then drawn in.

Versatility to the fore.

Maize yields of well over 70 t/ha, biogas, SHREDLAGE®, low-growing maize or other crops, such as whole crop silage or sorghum – ORBIS copes with every task. The three-stage structure of its transport discs ensures an even crop flow.

- The synchronised rotation of the cutting and intake discs enables a gentle crop transfer

- Sturdy tubular bars reliably prevent cob losses

- The geometry of the knives ensures a perfect cut

Optimal ground-contour following.

The characteristics of the terrain cease to matter when harvesting maize with the ORBIS. Precise ground-contour following is ensured by the redesigned tilting frame in combination with the enhanced CONTOUR / AUTO CONTOUR control system. With the skids in full contact with the ground, the AUTO CONTOUR control system automatically switches over to float position. In this way, excellent lateral compensation is ensured along with ground pressure control.

Low stubble height.

With the special design of its underside and its ability to adjust its tilt to maintain a parallel attitude to the ground, the ORBIS ensures short and even stubble across the entire working width. The ideal stubble which results is short, consistent, clean and shredded at the end for fast rotting.

The flat mounting angle with two different positions and the very flat design make it possible to attain stubble heights as low as 80 mm.

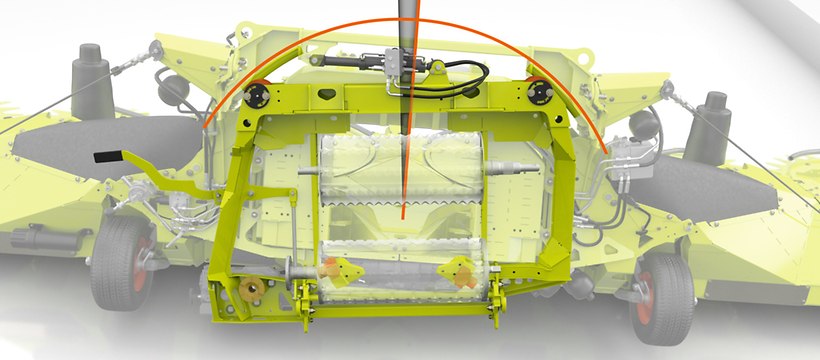

Integrated transport chassis.

For on-road travel, the ORBIS is folded to a width of 3 metres. The integrated transport system ensures compliance with road traffic licensing regulations and the actively controlled chassis enables ideal weight distribution for the whole vehicle. This makes for extremely comfortable driving at up to 40 km/h, thereby keeping transfer times between fields as short as possible.

As with all front attachments from CLAAS, on-road travel with the ORBIS is characterised by maximum safety and convenience. The compact, folded ORBIS provides the operator with an excellent view during on-road travel.

Easy maintenance.

Harvesting usually involves working within very narrow timeframes. Having to perform extensive maintenance work is a nuisance and also a cost factor, since it reduces productivity. This is why the CLAAS engineers have done all they can to keep maintenance requirements to a minimum. The key assemblies can be accessed quickly and easily while service intervals are reassuringly long.

Segmented design of transport and cutting discs

Easy access to clutches through maintenance panels

Integrated dipstick for checking oil levels

Long service intervals.

- All grease nipple points have a service interval of 250 operating hours

- All lubrication points are easily accessible for you

- A gearbox oil change is required after the first year and then every 2,500 operating hours

- All wear parts can be replaced by you quickly and easily

- Easy access to gearbox and clutches through maintenance panels

PREMIUM LINE for ORBIS.

Highly wear-resistant parts are recommended for extreme operating conditions, where there is a high proportion of sand, for example, or extended periods of operation.

Guaranteed durability.

It is often the case that every minute counts during the harvesting period. Time-consuming maintenance work is a nuisance and also a cost factor as it reduces the number of productive hours – along with your profit margin.

With ORBIS, wear-resistant parts ensure high long-term reliability:

- The knives have a tungsten carbide coating to increase their service life

- The speed differential between the knife disc and the transport disc creates a self-sharpening action

- The knife discs and transport discs have a modular structure comprising six segments and are easily accessible; as a result, in the event of damage, only the segment concerned needs to be replaced, rather than the entire unit.

Extremely maintenance-friendly design.

- Lubrication is only required every 250 operating hours

- All lubrication points are easily accessible

- A transmission oil change is not required until after the first season (500 operating hours) and then after another 5 years (2,500 operating hours) (input gearbox every 500 operating hours).

- All wear parts can be replaced quickly and easily