PICK UP 380 / 300.

Ever-increasing yields and more powerful forage harvesters make sense only if the crop can be taken up cleanly and the design is both robust and easy to operate. The PICK UP 380 and 300 front attachments meet these requirements with a wealth of features.

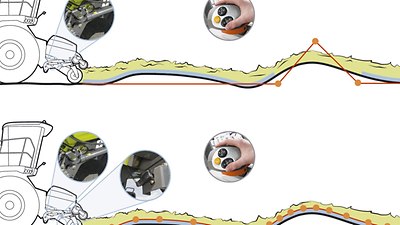

PICK UP with two variable and independent drives for the intake auger and pick up reel.

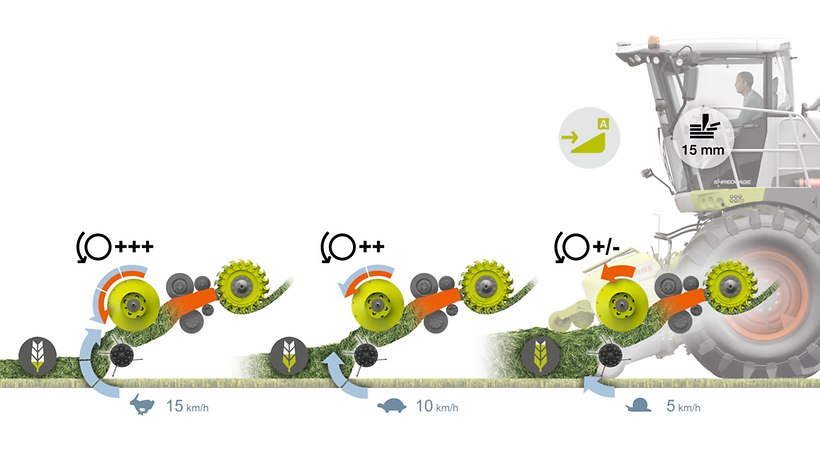

The pick-up reel is driven hydraulically. The independent adjustment of the reel speed to the ground speed enables an appropriate crop feed to the intake auger.

The drive for the intake auger is transmitted via the quick-release coupler. Speed adjustment is performed automatically in accordance with the set length of cut and, from 5 km/h, also in relation to the ground speed. The consistent crop transfer to the precompression rollers ensures optimal use of the capacity of the JAGUAR.

Recommended usage scenario: when it comes to delivering the highest standard of performance and maximum throughput in extreme conditions, the dual drive is the right solution; for example, when handling high yields at a very low ground speed or when operating at a high harvesting speed with low crop volumes.

Advantages:

- Compared with the standard version, greater throughput is possible in extreme conditions. A very consistent crop flow and efficient crop collection are additional benefits.

Crop flow.

The powerful, controlled rake with four or five tine rows enables a clean crop take-up. Furthermore, the guide wheels (which can be adjusted without tools) are fitted at the same height as the rake.

The double roller crop press and the large auger diameter ensure an excellent crop flow. The optional spring-loaded intake auger increases throughput when handling large swaths.

The auger speed is matched to the set chop length by means of the 3-speed transmission or by substituting the sprockets. The variable front attachment drive allows the machine performance to be matched optimally to the field conditions.

Suspended frame for PICK UP 300 and 380.

The main frame supports the torsion-suspended rake and the floating intake auger. The suspended frame is attached to the main frame by means of a central pin, three arms and a spring to return the frame to the neutral position. This arrangement enables ideal freedom of movement for optimal ground-contour tracking and high-performance crop pick-up.

Loss-free harvesting with the CLAAS CAM PILOT.

The CLAAS CAM PILOT takes control of the task of steering during the swath pick-up process – thereby making it possible to attain working speeds of up to 15 km/h without fatiguing the operator. Furthermore, the operator is able to concentrate much better on filling the transport vehicle for a loss-free harvest.

The CLAAS CAM PILOT detects the swaths in three dimensions and applies the appropriate steering correction automatically. As usual, it is activated via the control lever and deactivated by turning the steering wheel.

Optimal accessibility.

Excellent accessibility is one of the key characteristics of the PICK UP family. For example, during the reversing procedure after detection of a foreign body, the roller crop press is automatically raised hydraulically (optional raising of the intake is also possible). As well as making it easier to search for foreign bodies after the presence of metal or a stone has been detected, this arrangement allows wear parts to be replaced easily.

Spare wheel.

CLAAS offers a spare wheel carried with the PICK UP with a choice of mounting positions.